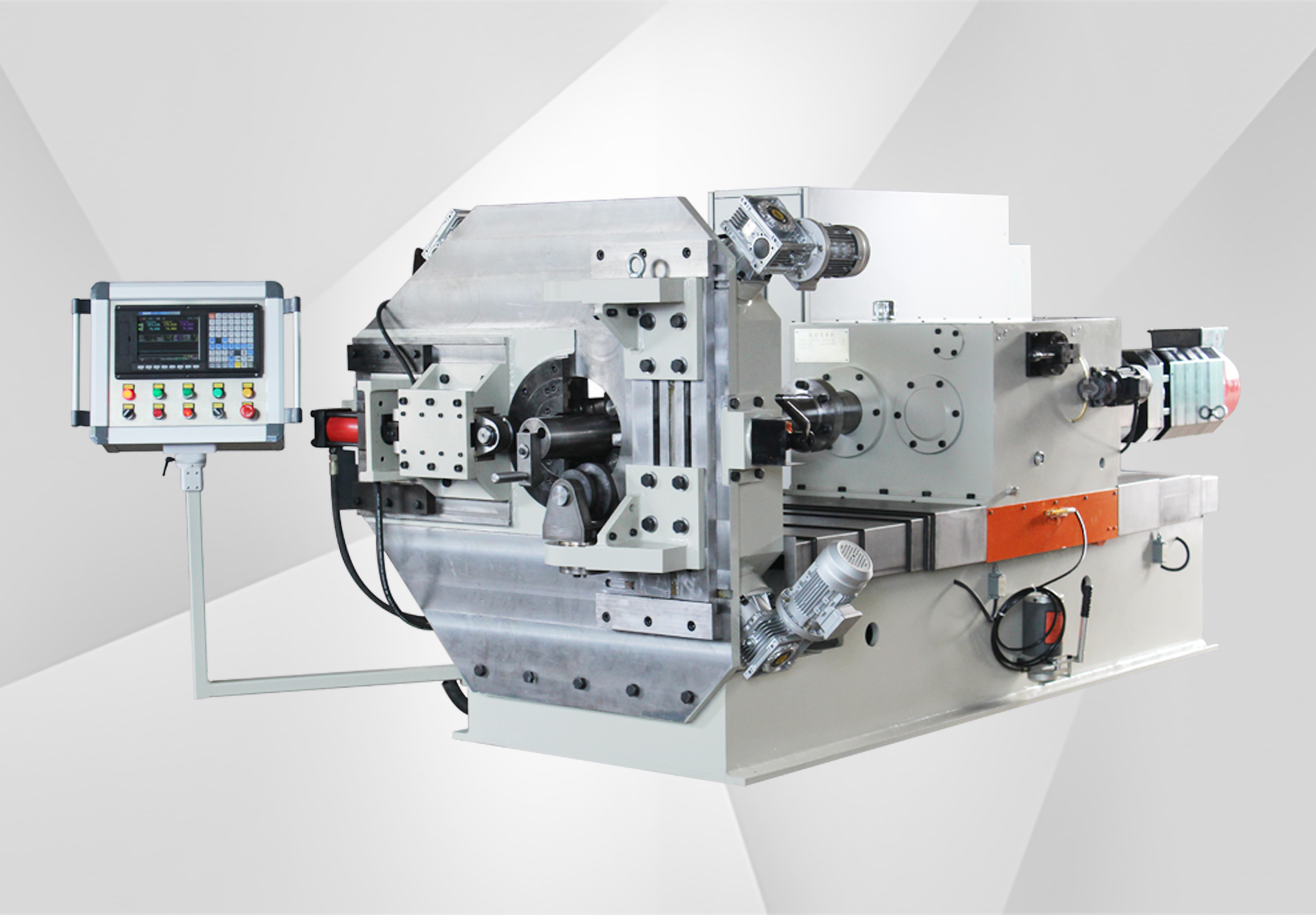

CNC Spring Hot Coiling Machine

CNC Spring Hot Coiling Machine Main Functions

1. Two sets of servo motors respectively control the number of turns and pitch of the spring;

2. G code programming, the control form is more flexible, the program can be stored, the production process can be controlled by programming, and the rolling speed is adjustable;

3. It can flexibly control the helix angle of the end ring and the pitch of the middle part, and control the height of the spring, without manual intervention after the winding is completed;

4. The reducer uses a servo-dedicated planetary reducer, with large torque, high transmission efficiency, no refueling, and lifelong maintenance-free;

5. Automatically pull the mandrel and unwind the spring, and the rolling process is automatic;

6. The beginning and end do not require human intervention, and can be quenched directly;

7. Mandrel with air cooling;

8. The direction of the feeding wheel is adjustable.

9. The position of feeding and ending part can be adjusted by a screw.