Hot Forging Automatic Production Line

Hot Forging Automatic Production Line

1. The raw material is bar steel, and the automatic bar steel cutting machine is used to cut the material.

The cut material is flat at both ends. The head and end materials of the bar are automatically separated and enter the waste area.

The good materials is conveyed into the storage bin of the fully automatic feeding machine.

2. The automatic feeding machine will push the material into the hearth furnace position of the induction heating machine

according to the set frequency, and automatically push it out after heating, without the need for human supervision.

3. The heating equipment adopts induction heating, and the material is pushed into the heating furnace by the automatic feeder, and the frequency is automatically heated according to the heating progress.

4. The heated workblank is also slid into the guide tube of the hot forging CNC synchronous manipulator from the intermediate frequency protection control exit through the slide,

and the manipulator clamps the workblank into the mold and heat-acid-formed.

5. Install the control buttons of the shearing machine, intermediate frequency and automatic feeding machine near the operator.

One nut hot forging production line only needs one person to operate (one person can take care of the feeder and the CNC).

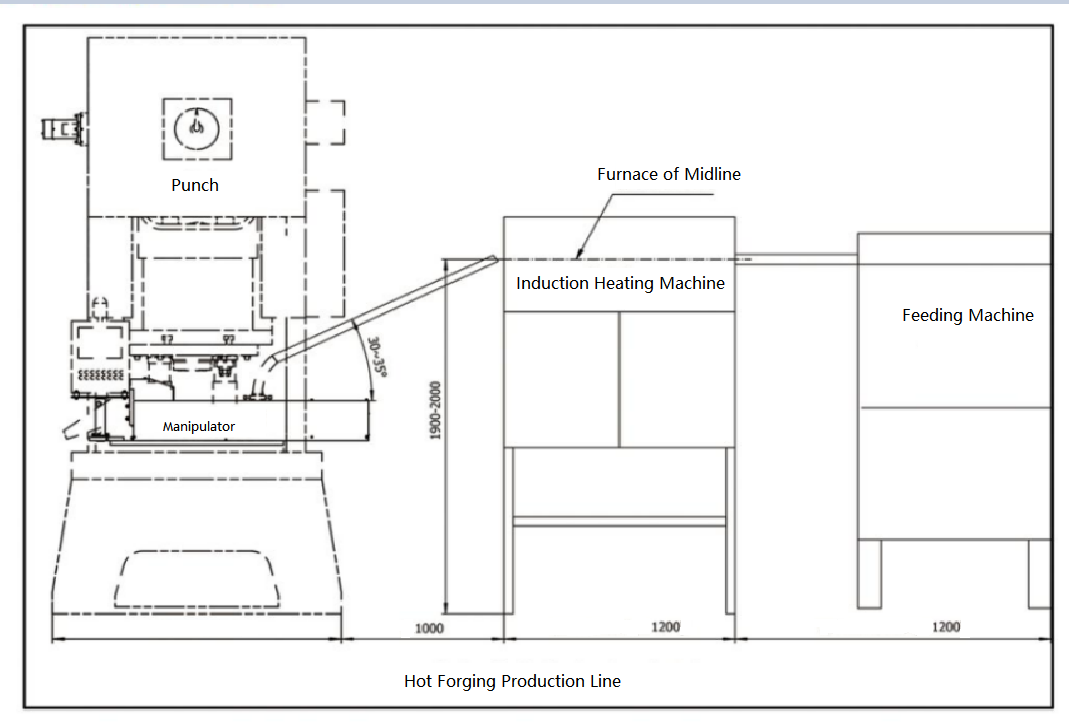

Equipment placement diagram: